THERMAL MEASUREMENT INSTRUCTIONS FOR LENSES AND REFLECTORS

BACKGROUND

- Thermal management must be considered carefully with LED luminaires because heat reduces LED lifetime and light output

- Infrared (IR) imaging and thermocouple measurement systems can be used for monitoring temperatures in LED applications in certain situations

- Absorption of radiant flux by thermocouple leads must be considered carefully

- Emissivity of target surface must be known if IR camera is used

LENS TEMPERATURES

|

|

REFLECTOR TEMPERATURES

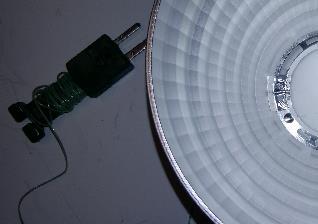

- Attach a thermocouple on surface of the reflector with a small aluminum tape and monitor temperatures until they are stablized.

- Paint target area, attach a tape which emissivity is known or remove metallization on outer surface of the reflector and take an IR image from that area after temperatures are stabilized.

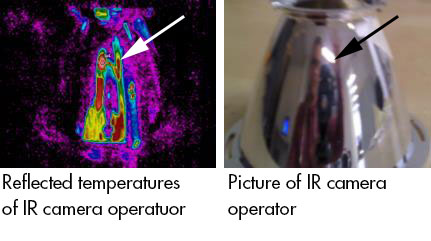

IR IMAGING FAILURE

- Low emissivity surfaces are challenging to measure with an IR camera because reflected temperatures can be seen in the IR image.

- Target surface’s emissivity must be known and correct value must be set for IR image.

COB LED TEMPERATURES

|

|

SUMMARY

- IR imaging is preferred method for lens and reflector temperature measurements.

- Tiny thermocouples (AWG 40 is recommended) can be used to measure LED case, PCB and heat sink temperatures where radiant flux doesn’t interfere and target surfaces cannot be exposed to IR camera

The information contained herein is the property of LEDiL Oy, Joensuunkatu 7, FI-24100 SALO, Finland and is subject to change without notice. Please visit www.ledil.com for additional information, such as the latest photometric files, 3D mechanical models, and application notes relating to handling, gluing and taping.