GUIDE TO TIR LENSES

SEARCH FOR TIR OPTICS:

RELATED CONTENT:

LEDiL General Installation Guide

Are reflectors becoming redundant

Application examples & guides

WHAT IS A TIR LENS

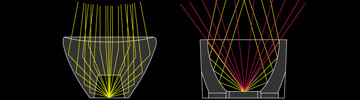

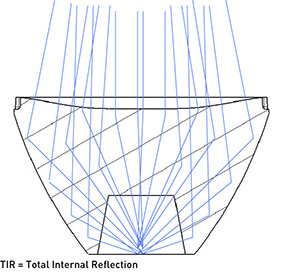

Most typical lenses in the LEDiL standard product range are the cone-like lenses. These lenses are often called TIR lenses as a big part of their design relies on total internal reflection. Typically TIR lenses are rotationally symmetrical designs which give a nice round light distribution. The lenses can be designed in arrays for multiple LEDs or have mechanical details included to aid mounting.

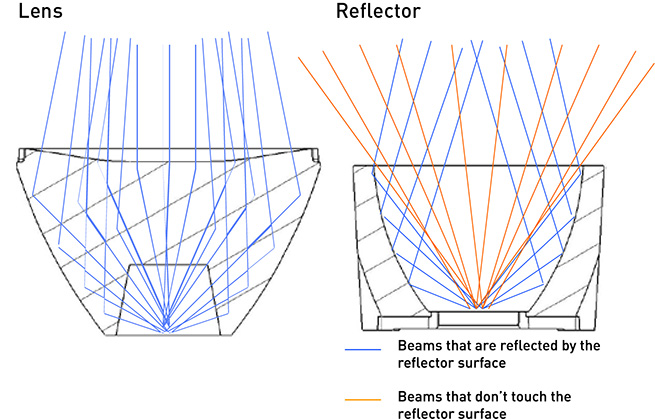

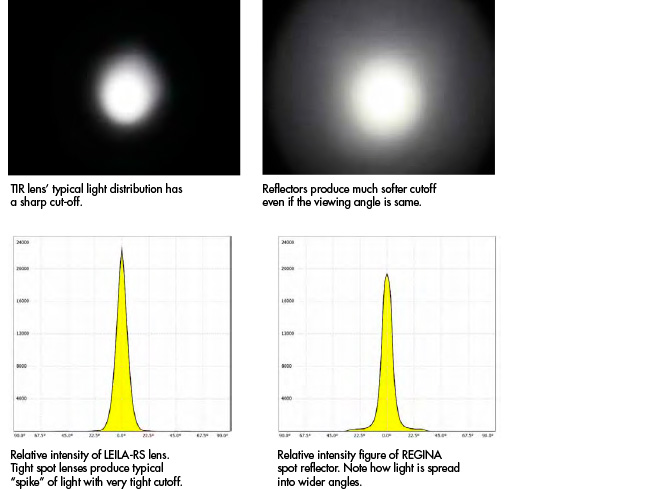

TIR LENS VS. REFLECTOR

The basic working principle is the same for both TIR lenses and reflectors, but TIR lenses have more control over light. With reflectors a big part of the light doesn’t “touch” the reflector and this light can’t be controlled in any way. This difference can easily be seen with tight spot optics as reflectors usually don’t have as sharp a cutoff as TIR lenses.

LENS TYPES

TIR lenses are arranged in different categories depending on optical performance. Size of the lens and LED affects the optical performance, so exact FWHM angles etc. can’t be specified. The following lens types can be found in most of our TIR lens families. Above, from left to right:

1. Real Spot (-RS), 2. Smooth Spot (-SS), 3. Diffused Spot (-D), 4. Medium (-M/-M2), 5. Oval (-O) and 6. Wide (-W/-WW/-WWW).

Above, from left to right:

1. Real Spot (-RS), 2. Smooth Spot (-SS), 3. Diffused Spot (-D), 4. Medium (-M/-M2), 5. Oval (-O) and 6. Wide (-W/-WW/-WWW).

| RS | SS | D | M/M2 | O/O-90 | W/WW/WWW | |

|---|---|---|---|---|---|---|

| Typical FWHM range | 4°-25° | 8°-25° | 8°-25° | 18°-35° | 8°-20°, 40°-50° | 35°-80° |

| Cd/lm peak | Very high | High | Moderate | Low | Low | Very low |

| Colour mixing | None | Low | Moderate | Moderate | Low | Moderate |

| Lens surface intensity at 80° (disability glare) | Very low | Low | Moderate | Moderate | Low | Moderate |

REAL SPOT (-RS)

Real Spot lenses are the tightest spot optics in the lens family. The main purpose for these lenses is to create high cd/lm peak and the design excludes elements that would have color mixing capabilities. This might lead to minor problems in the light distribution. Real Spot lens can be easily identified as it has fully polished surfaces and some lenses are hollow in the middle.SMOOTH SPOT (-SS)

The main difference between Smooth Spot and Real Spot lenses is the polished “pillow” surface on the Smooth Spot lenses. This kind of design gives better quality light distribution, but at the same time reduces the cd/lm peak and widens the beam.

DIFFUSED SPOT (-D)

Diffused Spot lenses have the smoothest light distribution pattern from the three spot lens versions. Cd/lm peak is a little lower than Smooth Spot lenses but the FWHM angle is about the same. The top surface has light diffusive treatment that helps with color mixing, but at the same time increases the chance of disability glare.MEDIUM (-M/-M2)

The light distribution of the Medium lenses falls between Spot and Wide lenses. Some lens families have more than one Medium type lenses which are identified with the number 2. Typical Medium lenses can be identified from small “pillow” surface treatment that resembles fly-eyes, but few have rough diffusive surface treatment.

OVAL (-O/ -O-90)

The light distribution pattern on oval lenses is wider on one axis. This is normally achieved with parallel grooves on the top surface. Oval-90 version is rotated 90° from the standard Oval version.WIDE (-W/ -WW/ -WWW)

Wide lenses have the widest light distribution in the TIR lens families. The more W letters there are the wider the light distribution is. Top surface of the lens normally have rough diffusive treatment, but some lenses might have medium sized “pillow” treatment, warped surface or both.

MECHANICAL LENS TYPES

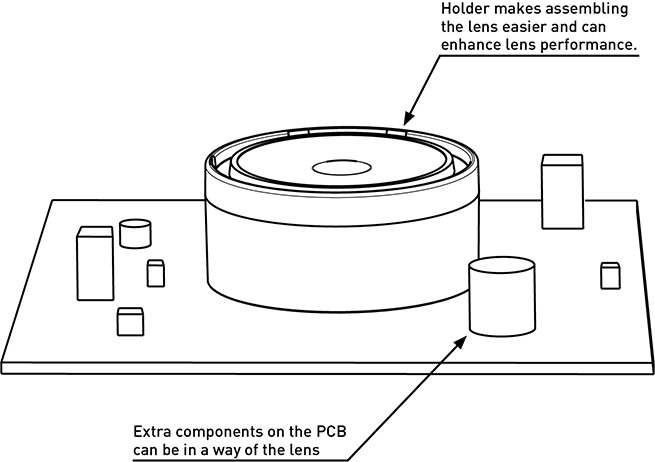

LENSES WITH HOLDER

+ mechanical cutoff shield+ white holder can enhance the performance

+ tape option

– extra components on the PCB can be in the way

– sealing needs glass plate

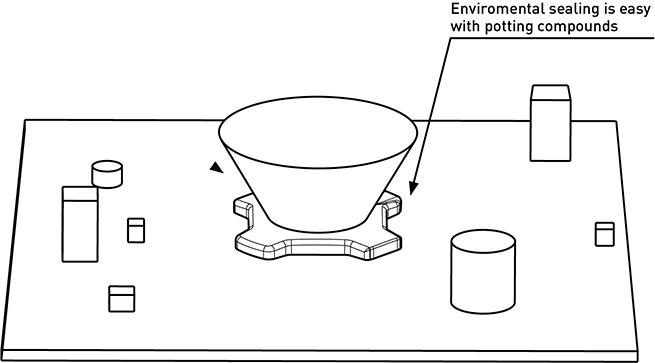

LENSES WITH LEG

+ sealing with potting material+ single component

+ tape option

– extra components on the PCB can be in the way

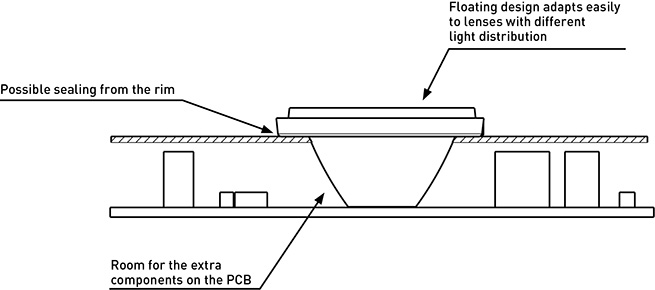

LENSES WITH RIM

(also lenses without holder)

+ floating design (lenses can be changed easily)+ room for extra components on PCB

+ works for multiple LEDs

(+possible sealing from the rim) – no position elements

– no tape

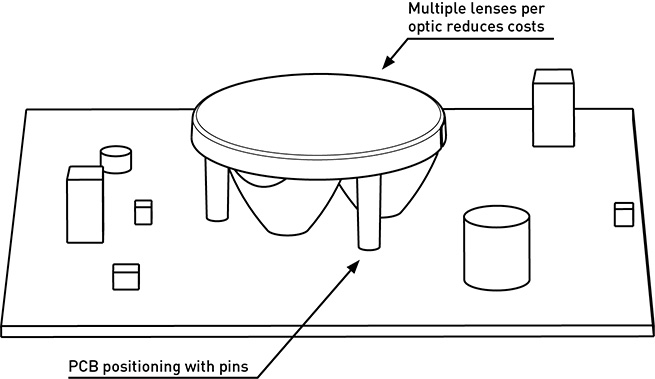

MULTILENSES

+ price per optic+ PCB positioning

+ Standard sizes (bulb replacements)(+sealing from from the rim)

– less freedom for design

The information contained herein is the property of LEDiL Oy, Joensuunkatu 13, FI-24100 SALO, Finland and is subject to change without notice. Please visit www.ledil.com for additional information, such as the latest photometric files, 3D mechanical models, and application notes relating to handling, gluing and taping.