NEWS

RELATED PRODUCTS:

RELATED CONTENT:

Introduction to retail lighting

Introduction to retail lighting

Illuminating supermarkets with LEDiL optics

Illuminating supermarkets with LEDiL optics

Effective fashion retail lighting

Effective fashion retail lighting

Guide - Retail lighting optics

Guide - Retail lighting optics

Low contrast retail lighting with LINDA and ELISE

Low contrast retail lighting with LINDA and ELISE

High contrast retail lighting with DAISY and ILONA

High contrast retail lighting with DAISY and ILONA

Track light luminaire with MOLLY

Track light luminaire with MOLLY

Track light luminaire with CARMEN-70 and shade

Track light luminaire with CARMEN-70 and shade

Track light luminaire with ILONA

Track light luminaire with ILONA

ILONA-RS with LensVector beam shaping lens

ILONA-RS with LensVector beam shaping lens

Track light luminaire with OLGA

Track light luminaire with OLGA

Track light luminaire with ALISE/ELISE

Track light luminaire with ALISE/ELISE

Downlight luminaire with DAISY-2X2

Downlight luminaire with DAISY-2X2

Supermarket lighting with MOLLY

Supermarket lighting with MOLLY

Retail lighting out of the box for sports box with FLORENCE-3R

Retail lighting out of the box for sports box with FLORENCE-3R

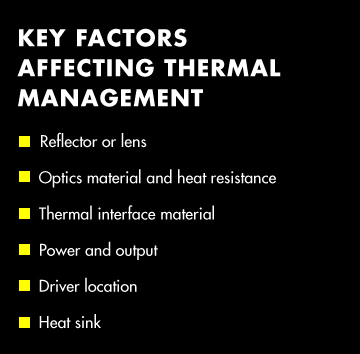

How to avoid thermal problems in powerful luminaires

High in power and small in size is an equation for luminaires that can be solved by making good choices in luminaire design. Find out what you can do to ensure your luminaire design takes key factors into consideration and allows you to be smart about your optics choices.

In lighting the majority of applied electrical power is converted to waste heat. Due to the lack of space for a heat sink there is a risk of overheating and consequently a decrease in the operating life of the LED. Also increasing temperature can have an impact on light wavelength performance.

Despite of that, there are several applications that require the use of powerful luminaires. This is ideally the case in retail environments and architectural lighting. At the same time, in both environments the aim is to create a highly visible effect from invisible sources. Technically speaking this means that the lenses can be quite large in size while luminaires need to be as compact as possible, meaning there is not a lot of space for the heat sink. Display windows, which need to be lit with a light source powerful enough to compete with natural daylight, are a prime example of this.

So, what should you consider in your design to avoid the thermal pitfalls that often arise in powerful luminaires?

Optical materials

In the heart of every luminaire - close to the source of heat and surrounded by almost airtight design elements – the optics are located. Thus, the material choice of optics plays a key role. So, choose wisely and make conscious decisions on what optics materials you use.

There is a variety of optical materials such as aluminum, silicone, PMMA and PC. Each material has specific thermal properties.

LEDiL reflectors are mostly made from polycarbonate with different methods for metallization.

One great reflector option is ELLA, a reflector made of high temperature PC (APEC). ELLA offers great resistance to impact and higher heat resistance compared to standard plastic reflectors.

If an even more heat resistant material is needed, the solution is aluminium. Solving thermal issues in a luminaire can be done e.g. by choosing a reflector such as the newly released ALISE product family. ALISE is a heat resistant aluminium reflector offering premium light quality to any track- or downlight luminaires with the ability to withstand high heat.

On the other hand, lenses offer full control of the light meaning more concentrated spot beams and reduced spill light. What are the differences in lens materials?

Silicone lenses are the toughest of all and provide excellent heat resistance as well as optical excellent optical performance with even better efficiency than glass. A prime example for high lumen output lighting with silicone lenses is our latest silicone jewel called SAKURA. These outstanding features however come with a higher price tag.

PMMA is a rigid lens material with a high light transmission rate and due to its higher efficiency can achieve higher luminaire power. You can opt for a compact yet powerful choice of lens such as OLGA with wide support for powerful LEDs.

PC offers great resistance to impact and is known for good heat resistance. At the same time, it absorbs more heat. In industrial applications HB-IP-2X6 could be the lens of your choice. It is an ideal fit where mounting height is elevated to more than 10 m and the ambient temperature is high.

Minimize heat from the LED driver

Taking the LED driver location into consideration makes a considerable difference in avoiding thermal issues. For example, placing it outside of the luminaire help to ensure that driver components do not increase heat within the light fixture and additionally, one LED driver can be used for several luminaires. Keeping the driver on the outside of the luminaire serves double duty as placing it outside of the luminaire also helps in the mission to create a luminaire that is compact.

Maximize heat sink benefits

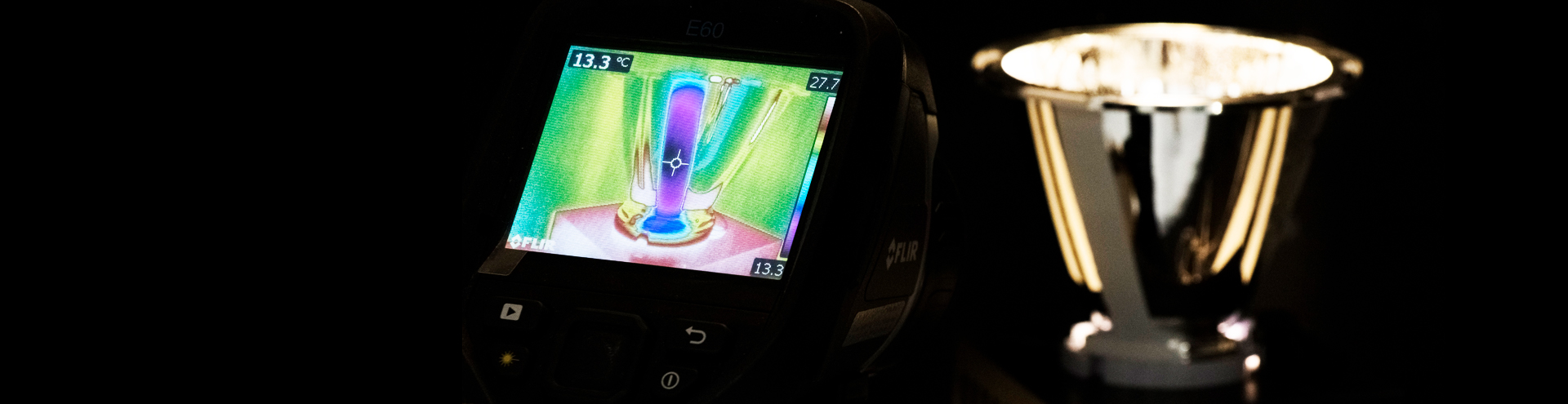

Heat sinks are the part of luminaires that absorb and dissipate heat away from the LED and help to cool the LED. Heat sink size, form, orientation and ambient temperature together with the air flow play a significant role play a significant role in maximizing the benefit of the heat sink in luminaires.

In the end everything affects the overall results and even the smallest details can have a huge impact. How well and how the connections are made between the LED and heat sink is one crucial element to this. Thermal paste is a good fit as it decreases thermal resistance and improves thermal conductivity between parts. It has been observed that replacing a thermal pad with thermal paste, can result in a huge temperature drop in the LED unction temperature. And while the connecting material is thin and flexible, the connection between heat sink and LED need to be pressed perfectly. Avoiding air gaps helps to ensure ideal cooling performance due to thermal resistance.

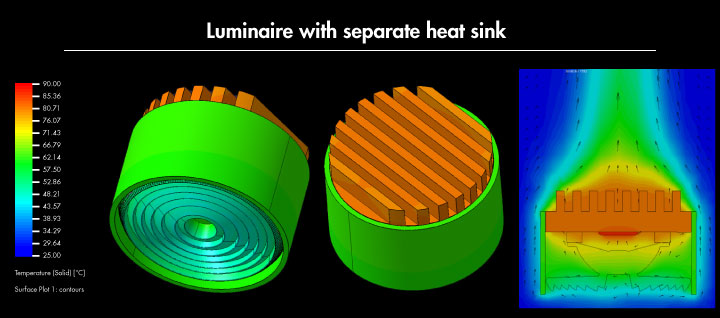

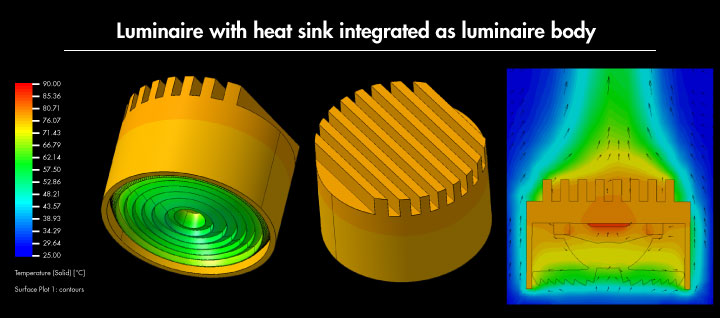

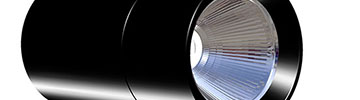

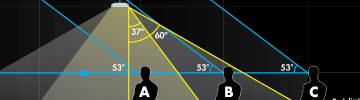

We simulated an example by comparing two track light designs and their maximum lumen output before lens maximum temperature of 80 °C is reached. Luminaire A is equipped with a separate heat sink. In the design of Luminaire B the heat sink is integrated in the overall design of the luminaire.

Luminaire A with separate heat sink. Maximum power 17 W and 2200 lm output.

Luminaire A with separate heat sink. Maximum power 17 W and 2200 lm output.

Luminaire B with heat sink integrated as the whole luminaire body. Maximum power 22 W with 2800 lm output.

Luminaire B with heat sink integrated as the whole luminaire body. Maximum power 22 W with 2800 lm output.

In both luminaires the maximum service temperature of the lens is 80 °C. As luminaire B distributes the heat on a larger area, it can be used with higher power and this results in a higher lumen output. Overall this means that luminaire B – even though being the same size as luminaire A - can output 27 % more lumens thanks to the thermal and luminaire design.

Be smart about your choices and keep cool!

If you would like to hear more or have questions related to good thermal management in LED luminaires and what optics to choose, click here and drop us a line.

You can also check the LEDiL Installation guide for more information about optical material properties.

RELATED PRODUCTS:

RELATED CONTENT:

Introduction to retail lighting

Introduction to retail lighting

Illuminating supermarkets with LEDiL optics

Illuminating supermarkets with LEDiL optics

Effective fashion retail lighting

Effective fashion retail lighting

Guide - Retail lighting optics

Guide - Retail lighting optics

Low contrast retail lighting with LINDA and ELISE

Low contrast retail lighting with LINDA and ELISE

High contrast retail lighting with DAISY and ILONA

High contrast retail lighting with DAISY and ILONA

Track light luminaire with MOLLY

Track light luminaire with MOLLY

Track light luminaire with CARMEN-70 and shade

Track light luminaire with CARMEN-70 and shade

Track light luminaire with ILONA

Track light luminaire with ILONA

ILONA-RS with LensVector beam shaping lens

ILONA-RS with LensVector beam shaping lens

Track light luminaire with OLGA

Track light luminaire with OLGA

Track light luminaire with ALISE/ELISE

Track light luminaire with ALISE/ELISE

Downlight luminaire with DAISY-2X2

Downlight luminaire with DAISY-2X2

Supermarket lighting with MOLLY

Supermarket lighting with MOLLY

Retail lighting out of the box for sports box with FLORENCE-3R

Retail lighting out of the box for sports box with FLORENCE-3R

All retail lighting optics

All retail lighting optics  LEDiL Installation guide

LEDiL Installation guide  Lighting that sells

Lighting that sells  Dark Light concept

Dark Light concept  Aprilia2 shopping mall lighting with LENA

Aprilia2 shopping mall lighting with LENA